An open-source pressure sensor data logger for wave measurement

The Open Wave Height Logger (OWHL) is an inexpensive open-source pressure transducer data logger based on an Arduino microcontroller that can be used to characterize wave conditions for deployments lasting multiple months. Our design criteria centered around simplicity, longevity, low cost, and ease of use for researchers. Housed in ubiquitous polyvinylchloride (PVC) plumbing and constructed primarily with readily available materials, the Open Wave Height Logger (OWHL) can be fabricated in a college setting with basic shop tools. The OWHL performs comparably to commercial pressure-based wave height data loggers during tests in the field, creating the opportunity to expand the use of these sensors for applications where sufficient spatial replication or risk of instrument loss would otherwise be cost-prohibitive.

The original design criteria and build goals for the Open Wave Height Logger focused on simplicity, durability, ease of construction and ease of use. In general, the OWHL is designed to be built from readily available materials and constructed using only basic shop tools found in most schools and field stations. Some of the build steps may require access to, the purchase of, or the fabrication, of some specialized tools and equipment. In practice, we found that with some steps, more uniform results were achieved when better tools and equipment were available above what might be found in a simple workshop environment.

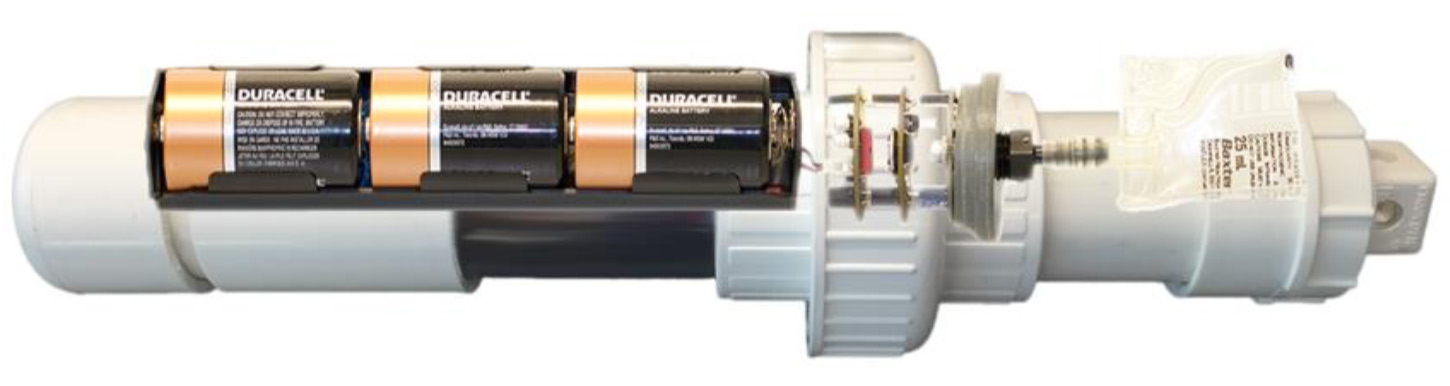

The OWHL housing is built using readily available, standard schedule 40, 1.5” PVC pipe and fittings (Figure 1). The custom OWHL electronics boards are designed to fit within this pipe (internal diameter of ~ 3.9 cm). The 1.5” pipe and the required pipe fittings can be found at nearly any home improvement, plumbing supply store, or like many parts of the OWHL, can be ordered online. Our design incorporates a break-apart union joint providing easy access to the internal components; allowing for simple battery changes and retrieval of the SD Card’s data.

This guide starts with the assembly of the electronic components, followed by programming of the chips. The next steps involve the machining of the bulkhead fitting. This is followed by the modifications for the remaining housing parts and the assembly of the OWHL into its finished form. The guide finishes with a discussion of anchoring methods to secure the OWHL to the seafloor.

A materials list and a cut list are at the end of the instructions. Some dimensions in this document, particularly thread sizes and nominal pipe sizes, are given in Imperial units where there is not a directly interchangeable metric equivalent.